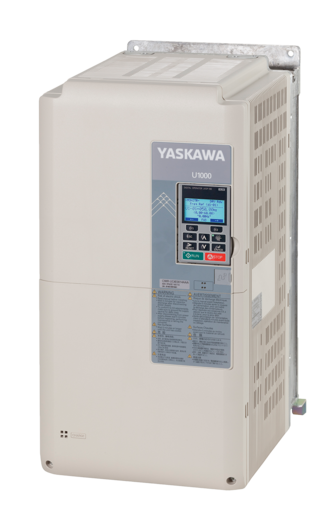

The U1000 is a highly efficient AC drive based on latest matrix converter technology.

U1000 is the perfect match for single motor drive applications with requirements to power regeneration and low harmonics such as lifts, escalators, HVAC machinery, hoists, centrifuges, and many others.

- Precise control of induction and permanent motors with or without encoder

- Highly efficient AC to AC direct conversion

- Automatic motor data adjustment

- 13 language full text keypad built in

Gain benefits in reliability and ship efficiency

U1000 is approved for global marine installation. Compared to 12 pulse systems the YASKAWA matrix design provides significant footprint and weight savings, keeping the THDi within the IEEE 519 limits.

Reliability and efficiency on board

U1000 matrix converter highlights:

- Fully regenerative AC to AC drive unit

- Low input distortion across a wide load and speed range

- IEEE-519 compliant (<5% THDi)

- Near unity power factor

- Compact design

- Functional safety (SIL3, PLe, Cat3)

- IM and PM motor control

- NK, DNV/GL, BV, ABS, LR, KR, CE, RoHS certification

Regenerated power

The best-suited solution for regenerative applications. The U1000 eliminates the need to install external braking units and braking resistors. It returns the regenerative and the braking energy directly back to the power supply.

- Saves energy

- Less heat generation, reduced need for ventilation

- No braking resistor – greatly reduced risk of fire

- Less maintenance

- Less parts

- Compact design

With full power regeneration capability, the U1000 offers great energy saving potential while sinusoidal input currents and a power factor close to one reduce stress on grid components like transformers and power lines. With an ultra-compact shape, the U1000 is the first choice for innovative, energy-efficient drive solutions with or without power regeneration.

| Type | Low Harmonics Regenerative Matrix Converter |

| Input Voltage/ range | 200 to 240 Vac 50/60 Hz (-15% to +10%), 380 to 480 Vac 50/60 Hz (-15% to +10%) |

| Motor Type | Permanent magnet motor, Induction motor |

| Control Method | V/f Control (V/f), V/f Control with PG (V/f w/PG), Open Loop Vector Control (OLV), Closed Loop Vector Control (CLV), Open Loop Vector Control for PM (OLV/PM), Advanced Open Loop Vector Control for PM (AOLV/PM), Closed Loop Vector Control for PM (CLV/PM) |

| Frequency control range | 0.01 to 400 Hz |

| Ambient temperature | -10 °C to +50 °C (IP00 enclosure) -10 °C to +40 °C (IP20/UL Type 1 enclosure) |

| Standards | UL508C, IEC/EN 61800-3, IEC/EN 61800-5-1, EN ISO 13849-1 Cat.3 PLe, IEC/EN 61508 SIL3 |

| Enclosure | IP00 |

| Control Inputs | 8 digital, 1pulse, 3analog(2V x 1(V/I)) |

| Control Outputs | 4relay, 1pulse, 2analog(V/I) |