YASKAWA GA700 – 0017

GA700 is the new versatile Yaskawa AC drive for industrial applications. Great flexibility, small dimensions, and built-in features allow an effortless integration. Smart tools like the Startup Wizard, data logging, the DriveWizard Mobile app, and many more assist during setup and troubleshooting to save valuable time. Offering world class YASKAWA quality, along with intuitive interaction and high flexibility, our new GA700 is meant to easily handle nearly any application.

Yaskawa GA700 drives for the crane applications comes with dedicated crane software keeping in mind the criticality of the crane applications. With the dedicated inbuilt crane software which keeps monitoring the operational parameters at all the times during the operation, makes sure that it is safe to operate your crane. Improved key functions make sure that the operation is stable.

Application areas include.,

- Hoisting : Used for lifting and lowering of the load

- Gantry or long travel

- Trolley or cross travel

- Slewing

- Jib or boom

Brake Release

The brake control ( open/ close) command is operated in such a manner that when the brake opens or closes the drive ensures that there is enough torque present at the output of the VFD to hold the load at the time of start and stop without rollback. With Yaskawa GA700 VFD the brake is operated after comparing the output frequency, output current and torque present. Thus, making sure that when the brake opens there is no dropping of load.

The smooth torque curves provided by Yaskawa GA700 drives assures that the whole operation of the crane is safe under all conditions.

KEY BENEFITS

- Full torque at zero speed* for brake operation during standstill increases brake lifetime and softens the movement (*requires speed sensor)

- Smooth motor operation reduces wear and tear of machines while transported goods are treated more gently

- Safe operations under all working conditions

- Built-in functional safety (STO, Safe Torque Off) does away with motor contactors reducing cost while improving machine reliability

- Automatic overload tripping prevention by lengthening acceleration and limiting the speed at heavy load condition

- SIL3 function is provided without a contactor

- Built-In brake control for safe brake operation: Independent Open/Close settings for optimal timing, Motor circuit check before brake lifting, Brake feedback signal monitoring

- Optimized motor control for both induction and permanent magnet motor.

| Type | Industrial Application Inverter Drive |

| Range | 200 V class: 0.55 – 110 kW 400 V class: 0.55 – 355 kW |

| Motor Types | Induction Motor (IM), Permanent Magnet Motor (IPM/SPM), Synchronous Reluctance Motor (SynRM) |

| Control | V/f and Vector control with/without encoder, EZVector |

| Output Frequency | 0 to 590 Hz |

| Braking Transistor | Built-in |

| Ambient Temperature | -10 to +50 °C (IP20), -10 to +40 °C (NEMA 1), up to +60 °C with derating |

| Protection Design | IP20 standard, NEMA Type 1-Kit (optional), IP55/NEMA Type 12 external heatsink (factory option) |

| Standards | CE, UL, cUL, EAC, REACH, RoHS |

| Functional Safety | Safe Torque Off (STO) according to IEC 61800-5-2, tested according IEC/EN61508 (SIL3) and ISO/EN13849-1 (Pl e, Cat. 3); TÜV Süd certified |

| Control Inputs | 8 digital, 3 analog (V/I), 1 pulse |

| Control Outputs | 4 digital, 2 analog (current/voltage), 1 pulse |

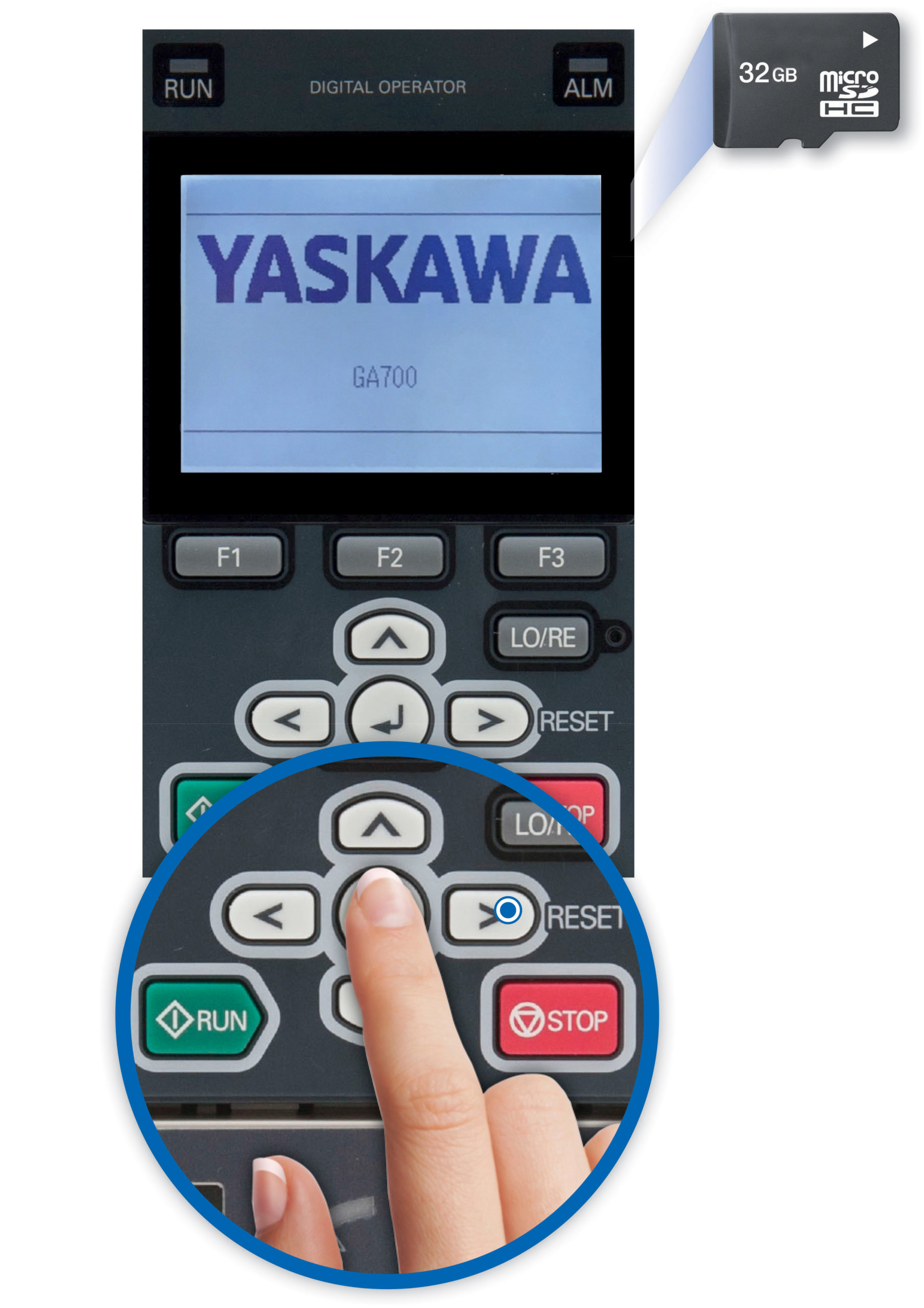

| Programming Interface | Mini-USB on the front cover; digital operator with Bluetooth (optional) |

| Further Functions | Integrated PID controller with sleep function Automatic balance of load level between two motors that operate the same load (droop control) Automatic main power loss ride through Speed Search function for smooth start of coasting motors Braking with over-magnetization for fast stop without braking resistors Energy-saving function Automatic restart after failure Overvoltage suppression |