Regular Downtime, less efficiency badly affects the productivity and economic resources of industries. As the industry evolves and process changes conventional methods of crane control does not provide better results.

Modernization of cranes is needed for the industries to improve the performance, efficiency by reducing the downtime and make it more competitive in the market.

The biggest challenges faced while using conventional system

- Burnt electric motors due to excessive starting current at the time of start (6 times the running current)

- High rate of failure of switchgear, rectifier unit, motor carbon brushes and slip-rings

- Burnt/damaged breaking resistors due to uncontrolled regenerative voltage

- Larger Panel Size required: Twice the switchgear is required due to the use of two motors

- Lower level of safety due to break operating dependency on switchgear

- Due to continuous operation of switchgear, heat dissipation inside RCS control panel is very high which affects operation of equipment

- Long downtime, delay of construction due to maintenance or replacement of equipment

- Very short lifetime of all used electrical and mechanical parts

- Too many components required: High maintenance time & cost

Why Modernization is necessary?

- Increase the machine’s performance and efficiency

- Reduce downtime

- Reduce Energy Consumption by reducing required running power (generator size) which has its big influence on reducing the diesel consumption

- Reduce Preventive Maintenance Costs; less mechanical and electrical jerks on system

- Smoothen the Operation (smoother speed, acceleration and deacceleration with no jerks)

- Increase the Safety Level of Machine Operation through reading some feedbacks and inputs/parameters before starting and during the operation

What We Offer?

Technologies are changing often. To improve performance, reliability and safety GULF-TECH Automation Yaskawa offers to upgrade your crane control system to meet the needs of industrial regulations. Our team is happy to support you with the below modernization solutions, which are installed and currently operational in many machines in the region.

Tower Crane Hoisting System modernization (RCS to VFD)

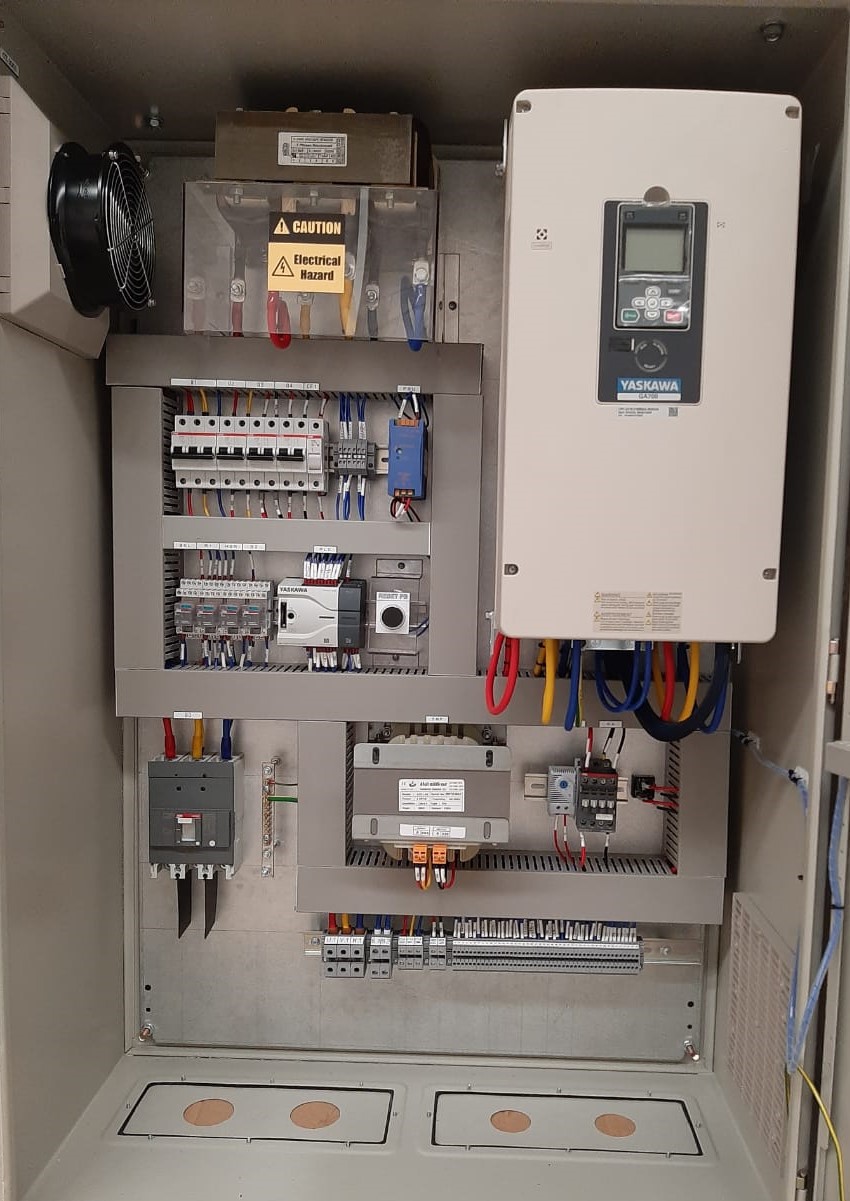

RCS system is an old system consisting of 2 motors that run in Direct On Line (DOL) with starting amperes reaching 6 times the nominal running amperes of each motor. this reduces the lifetime of the motor. GTA is able to offer you a complete package solution (VFD Panel with braking resistance) to have the best control on the hoisting system operation.

Tower Crane Slewing system Modernization (RCV/RTC/RTV to VFD)

- RCV/RTC/RTV is an old slewing system which controls the speed of the slewing motors by controlling the voltage supplied to them.

- After modernizing this old system to Inverter system, you will have much less breakdowns related to eddy current block and coil which are not integrated with the inverter system.

- Also your slewing motors are saved from burning due to the control of Voltage and Frequency as per the feedback from the motor current.

Passenger Hoist Main control Panel (DOL to VFD)

Once you have the VFD panel operational in your passenger hoist, then you would see big difference in regards to below:

- SAFETY – with Yaskawa GA7000 (with crane software) the hoist motor brakes would never open/activate unless the motor is holding the load/people at the required torque (which is fully controlled by the VFD) so no chance for load to slip or free fall.

- COMMERCIALLY – once in operation, you can reduce the Generator size (starting and running currents are controlled by the VFD and would be much less than DOL – Direct-On-Line start-up). As well as that, your preventive maintenance cost (Spare parts: gearbox pinions, brake discs, bearings.. etc.) would be reduced as your mechanical system will move at smoother speeds with no jerks and you would see less wear and tear for the same period of time. Also frequent breakdowns like motor winding flush and gearbox cracking/breaking would vanish at all.

- OPERATION – the operation would be much smoother and more precise, your operators and users would feel it.

Our Modernization solutions are delivered for major brands like, Alimak Hoist, PEGA Hoist, KNF Slewing, Comedil Luffing, Liebherr Slewing system & Hoisting, POTAIN Slewing system, Yongmao/zoomlion/Jianglu, GJJ/Orbit/BAODA with our YASKAWA CRANE and HOIST VFD’s and Accessories.