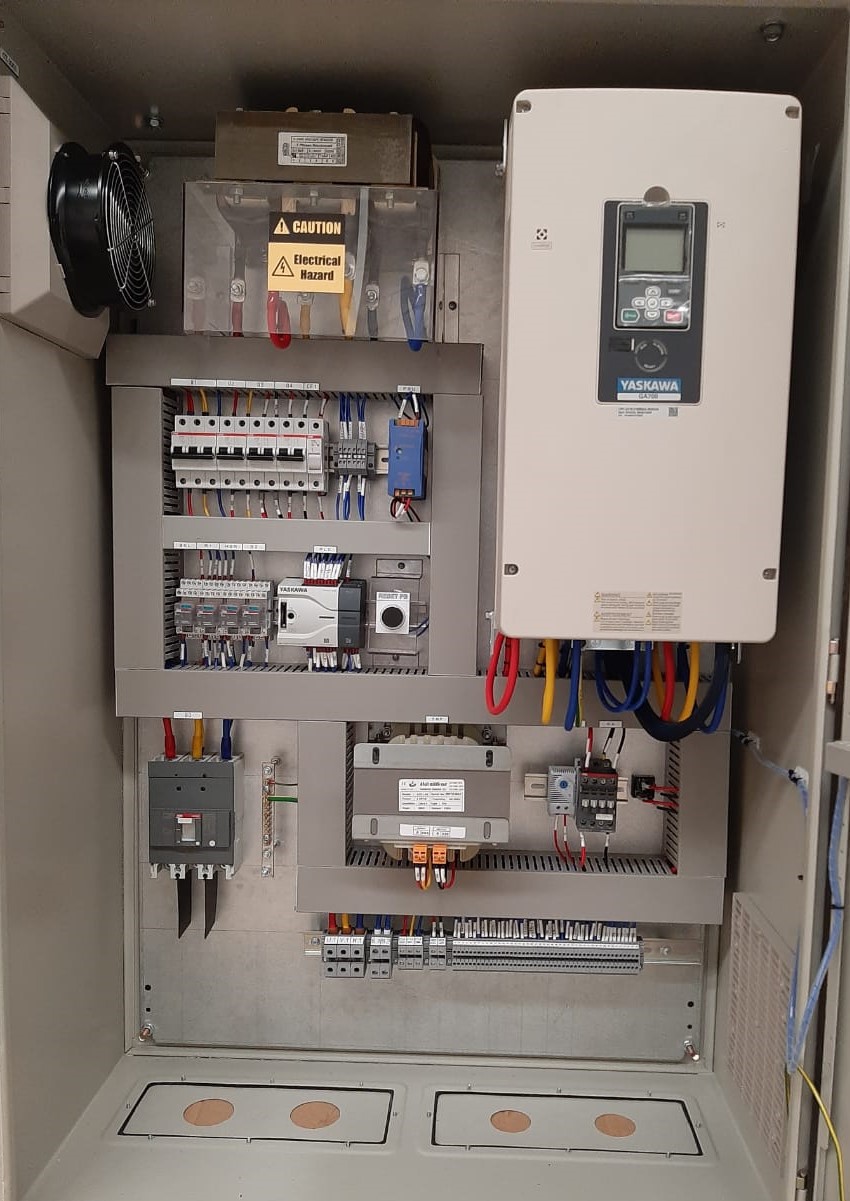

VFD based control panels are used in Crane and hoists applications. VFD panels are more efficient than conventional starter panels(RCS,DOL). It helps to improve performance, reliability and safety.

Crane control panel is custom designed to meet special demands. Panels are manufactured in a manner, to withstand harsh environmental conditions.

Direct Technical Support:

Our offer includes,

- YASKAWA inverter with a special crane software, made in UK / Japan with inbuilt braking unit and EMC Line Filter

- YASKAWA VIPA Controls PLC. It will simply the circuit and make the design easier and safe.

- REO Braking Resistors IP54, Made in Germany

- Ventilation Fan with filter and thermostat to control Fan operation

- All switchgear components used are of reputable brands

Our engineering team will perform entire process including site inspection, design, assembling and production of control panels with industrial standards. Programming, installation and commissioning is performed by our YASKAWA trained engineering team.

Why are we different?

- 4 Years Extended Warranty which is not offered by any other Inverter Manufacturer and can by attained only when buying from Local Authorized Sales Partners of YASKAWA

- Crane/Hoisting Special software; brake opening is controlled by inverter which increases the safety level of the Tower Crane/Hoist

- YASKAWA trained engineering team who are always available to support all our customers

- We are the only Authorized YASKAWA Service centre in the whole Middle East, where we do services for YASKAWA products sold by us

KEY BENEFITS

- Improves Machine’s performance and efficiency

- Safety, the VFD panel would never generate as much heat as the conventional control panels and there would be no risk of starting or catching fire at any point in time during operation. And the motor’s brake would never open/activate unless the motor is holding the load at the required torque (which is controlled by the VFD) so no chance for load slipping or load free fall.

- The operation would be much smoother and more precise, your operators and users would feel it.

- Preventive maintenance cost (Spare parts: gearbox pinions, brake discs, bearings, slip-rings, carbon brushes and springs.. etc.) would be less as your mechanical system will move at smoother speeds with no jerks and you would see less wear and tear for the same period of time. Also frequent breakdowns like motor winding flush and gearbox cracking/breaking would vanish at all.