Game Changing Soft Starters

The MVC4 Medium Voltage Series Soft Starter is designed to start AC motors in any fixed speed application. It provides maximum protection with “True Thermal Modeling,” while allowing smooth, stepless control of acceleration and deceleration. The MVC4 Series guarantees power control and protection for your most important assets.

- up to 15kV

- Special Application Options

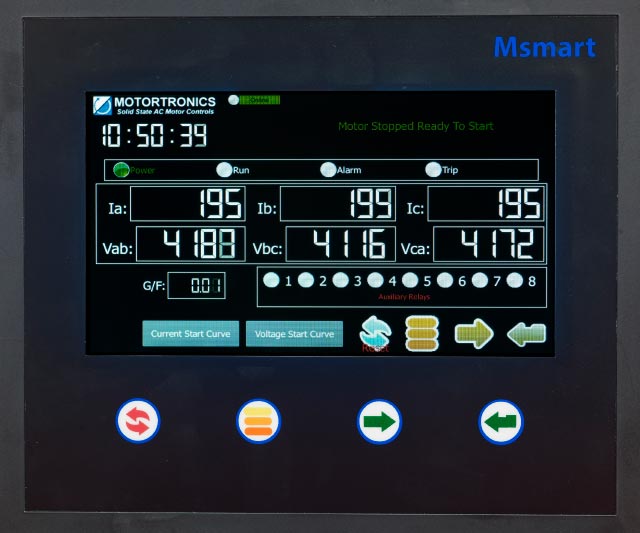

- Connects to Msmart

Direct Technical Support:

Highlights

Technical Details

Highlights

Features & Benefits

- Advanced motor protection relay and ramp features programmable via the keypad or a laptop computer.

- Fiber optically isolated low voltage compartment with up to 110kV BIL rating for safety and reliability.

- Built-in 120V control power transformer*; voltage and current metering.

- Load-break / fault-make rated disconnect switch with door safety interlocking.*

- Visible grounding bar for safe operation.

- Coordinated motor fuses with blown fuse indicators.

- Line isolation vacuum contactor.*

- Fully rated bypass contactor for increased thermal capacity and optional across-the-line starting.

- Heavy duty SCR stack assemblies with ring transformer isolation for reliable SCR gate firing.

- RTD Option accepts up to 12 RTD inputs.

- Zero sequence ground fault protection option.

- Top entry, bottom exit with room for stress cones.

- Removable entry plates for easy connections.

- NEMA 12 gasketed enclosure (NEMA 3R optional).

Advanced Protection

- True Thermal Modelling monitors the motor for excessive thermal conditions due to starting, running and even ambient conditions.

- Retentive Thermal Memory for continuous overload protection even after a complete power loss.

- MVC Plus remembers the last thermal condition of the motor, observes the off time via a real-time clock and adjusts the thermal model accordingly.

- Non-Volatile Memory stores the thermal memory without the need for batteries.

- True Time Thermal Tracking adjusts the thermal model for different cooling rates based on motor temperature, running state or power loss.

- Dynamic Reset Response Reset is only allowed after the motor has sufficient thermal capacity for a successful restart.

- Thermal Model Biasing adjusts for heating effects of phase current imbalance or optional RTD inputs.

- Flexible Setup Choose the level of overload protection.

- Programmable Trip Classes selectable from NEMA/UL Classes 5 – 30.

- Dual Mode Protection separate trip curves for start and run modes (example: Class 20 for start, Class 10 for run).

- Warning Levels can be programmed and assigned to one of six built-in output relays.

- Custom Trip Curve programmable based on the motor manufacturer’s data

- Remote or Automatic Overload Reset can be activated for unattended operations.

TechnicalDetails

| AC Supply Voltage | 2300, 3300, 4160, 6000/7200V, 11-15kV VAC +10% to -15%, 50/60 Hz line voltages |

| HP Ratings | Up to 10,000HP @ 7.2kV (800 Amps max) Up to 20,000HP @ 15kV (800 Amps max) Contact factory for higher rating requirements |

| SCR Overload Ratings | 500% – 60 seconds, 600% – 30 seconds |

| Power Circuits | Series strings of SCR powermodules (1, 2 or 3matched pairs of SCRs per phase depending on voltage rating) |

| SCR Peak Inverse Voltage | Line Voltage 2,300V, PIV Rating 6,500V Line Voltage 3,300V – 4,160V, PIV Rating 13,000V Line Voltage 6,000V – 7,200V, PIV Rating 19,500V Line Voltage 11,000V – 15,000V, PIV Rating 39,000V |

| BIL Rating | 2,300V – 7,200V: 60kV 11,000 – 15,000V: 110kV |

| Transient Voltage Protection | dv/dt circuits (1 per SCR pair) |

| Vacuum Bypass Contactor | Standard on allmodels, line start rated |

| Ambient Operating Conditions | 0 – 50°C (82° F to 122° F) (Optional -20° to 50° C with heaters) 5 – 95% relative humidity 0 – 3300 ft (1000m above sea level without derating) |

| Digital Control Unit (DCU) | Programmable keypad/operator with 2 lines x 20 character backlit LCD display. Status/Alarm LEDs (indicate: Power, Run, Alarm, Trip, Aux 1 – 8) |

| Programmable Features | Motor FLA, service factor, insulation class, Dual Ramp Adjustments – Two independent settings for: Initial Torque 0 – 100% of nominal torque, voltage or current, Current Limit 200 – 600% of motor FLA, Acceleration Time 1 – 120 seconds, Three Custom Curves Via plotted torque/time axis points, Pump-FlexTm Decel 1 – 60 seconds with begin & end torque adj Kick Start 0.1 – 2.0 seconds (10 – 100% voltage),Tach Feedback (option) Closed loop speed ramp |

| Motor and Starter Protection | Electronic Overload, Phase Loss Phase Imbalance, Phase Reversal Short Circuit Detection, Over / Under Current Over / Under Voltage, Shorted SCR / Shunt Tri p Starter Over-Temp, Coast Down Lockout Starts per Hour Lockout, Time between starts RTD Input (Option), Ground Fault (Option)g |

| Statistical Data | Percent of FLA, phase currents, kVAR, kVA, kW, power factor, demand, avg. start current, remaining thermal register, thermal capacity to start,measured capacity to start, time since last start, line frequency, phase order, RTD values (optional) |

| Enclosure | NEMA 12 with 3R optional (not for direct sun applications), top and bottom entrance plates, 11 gauge steel, ASA #61 gray powder coated paint |

| Communications | RS485 with Modbus RTU protocol or RS232 with windows interface Available Communications Options: Ethernet/IP, Modbus TCP, DeviceNet Profibus DP, PROFINET |